Cement is a global commodity, manufactured at thousands of plants. The industry is consolidating globally, but large international firms account for only 30% of the worldwide market.

The principal and most visible market for cement is the construction industry in a multitude of applications where it is combined with water to make concrete. Manufacturing industries in general account for one-third of global energy use.

Direct industrial energy and process CO2 emissions amount to 6.7 gigatonnes (Gt), about 25% of total worldwide emissions, of which 30% comes from the iron and steel industry, 27% from non-metallic minerals (mainly cement) and 16% from chemicals and petrochemicals production.

Cement production involves the heating, calcining and sintering of blended and ground materials to form clicker. As a result, cement manufacturing is the third largest cause of man-made CO2 emissions due to the production of lime, the key ingredient in cement.

Therefore, energy savings during cement production could lead to lower environmental impact. In the cement/concrete industry improvement of energy efficiency and reduction of CO2 emissions could be mainly achieved through two procedures:

- Changes in the manufacturing and production processes

- Adjusting the chemical composition of cement

Manufacturing and production processes can be improved by changing energy management and by investing in new equipment and/or upgrades.

Changes in the chemical formulation of cement have been demonstrated to save energy and reduce CO2 emissions, but their widespread adoption has thus far been hampered by the fact that developing a new industrial standard is complex and requires time.

This holds in particular for the cement industry which is a highly capital intensive and competitive sector with long economic lifetimes of existing facilities so that changes in the existing capital stock cannot easily be made.

The largest opportunities for improving energy efficiency and reducing CO2 emissions can be achieved by improving the cement manufacturing process. In the cement industry pyroprocessing (processing the raw material into cement under a high temperature, e.g., above 8000C) is a very common technological procedure, which accounts for 74% of the energy consumption in global cement/concrete industries.

Since the thermal efficiency through the use of this conventional technology of pyroprocessing is slightly higher than 30% on average, there could be considerable scope for improvements. Grinding and milling account for 5.8% of cement/concrete energy consumption.

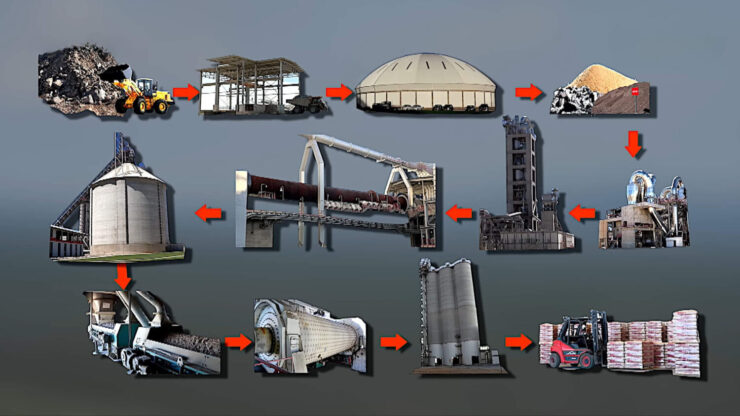

These operations have an energy efficiency ranging from 6 to 25% and also offer a large opportunity for energy saving. The following figure presents the cement production process.

Cement production process

The potential opportunities for improving energy efficiency and lower CO2 emissions in raw material generation and production of concrete are smaller than in cement manufacturing. For instance, CO2 emissions during transport could be reduced by replacing diesel fuel with biodiesel.

Normally, energy efficiency improvements proportionally reduce the emissions of CO2 generated from fossil fuel combustion and electricity generation. However, it should be noted that reducing CO2 emissions from cement manufacturing by a percentage proportional to energy efficiency improvements is not possible.

More than half of the CO2 emissions associated with cement/concrete are a result of the chemical reactions necessary for converting raw materials and not a result of the energy required to produce these reactions.

For example, if a near-zero CO2 emitting fuel (e.g. nuclear energy, biomass) were utilised for all pyro processing energy needs, then CO2 emissions could be reduced by 54%.

Energy use and CO2

One alternative method for reducing emissions involves replacing fossil fuels with waste or biomass in the cement production process. Cement kilns are particularly well-suited for this substitution because their high operating temperatures and the properties of the clinker product and limestone feedstock help purify the gases released during combustion.

In cement kilns, a wide variety of waste materials including used tires, wood, plastics, and chemicals are co-combusted in substantial amounts.

In Europe, cement plants in countries like Belgium, France, Germany, the Netherlands, and Switzerland have achieved average waste substitution rates ranging from 35% to over 70%, with some plants reaching 100% substitution using suitable waste materials. Achieving such high substitution rates necessitates a customized pre-treatment and monitoring system.

For instance, municipal solid waste must undergo pre-treatment to ensure consistent calorific values and feed characteristics. In the United States, the cement industry burns about 53 million used tires annually, accounting for 41% of all burned tires, equivalent to 0.39 million tonnes or 15 petajoules (PJ) of energy.

About 50 million tires, or 20% of the total, still end up in landfills. Carpets, another significant waste source, could also be diverted from landfills where they represent about 100 PJ of potential energy per year, to be used as fuel in cement kilns.

Despite the widespread use of these alternative materials, their application remains contentious due to the less stringent emission controls on cement kilns compared to dedicated waste incineration facilities.

According to International Energy Agency (IEA) statistics, the cement sector in OECD countries utilized 1.6 million tonnes of oil equivalent (Mtoe) of combustible renewables and waste in 2005, split evenly between industrial and wood waste. Globally, this sector used 2.7 Mtoe of biomass and 0.8 Mtoe of waste, constituting less than 2% of its total fuel consumption.

Technically, the potential exists to increase the use of alternative fuels to between 24 Mtoe and 48 Mtoe, potentially reducing CO2 emissions by 100 million to 200 million tonnes annually.

Another strategy to decrease energy and process emissions in cement manufacturing is to blend cements with higher proportions of alternative (non-clinker) feedstocks like volcanic ash, granulated blast furnace slag from iron production, or fly ash from coal-fired power plants.

The prevalence of using such blended cements varies significantly by region. Usage is high in continental Europe but remains low in the United States and the United Kingdom. In the U.S. and China, other clinker substitutes are added directly during the concrete-making process.

Ultimately, cement lacks a sustainable carbon-free alternative, and IEA scenarios suggest a significant dependence on Carbon Capture and Storage (CCS) technologies in cement kilns, including those employing oxy-fuel techniques.

Feasibility of Technology and Operational Necessities

In the cement pyroprocessing process it is important to keep in mind that waste materials combust and burn at different temperatures under different conditions. Therefore, solid waste fuels need to be introduced into the kiln in such a manner that they do not significantly change the temperature profile and chemical reactions in the overall pyroprocessing.

Sometimes it is necessary to add solid waste through a hatch or valve structure in the kiln shell, which implies a technical challenge and which partly offsets the efficiency gains and CO2 emission reductions. Finally, receiving and handling of alternate or waste fuels can raise technical liability and political concerns.

Cement manufacturing companies do not desire to be labeled as handlers of hazardous wastes and surrounding communities may have concerns about hazardous waste transport and handling in a nearby cement plant.

Furthermore, blended cements offer a major opportunity for energy conservation and emission reductions, but their use would in many cases require revisions to construction standards, codes and practices.

Of the cement production chain steps, grinding and milling operations are rather energy inefficient. As mentioned before, typical systems routinely run at 6 to 25% on-site energy efficiency.

Energy improvement of grinding and milling could be increased by using modern mill systems which comprise several units of process equipment with high-pressure, twin-roll presses, tube mills, ball mills, and conventional or high-efficiency separators.

Status of the Technology and its Future Market Potential

The primary opportunity for reducing energy use and CO2 emissions in the production of cement and concrete lies in enhancing cement pyroprocessing. Pyroprocessing is the process that converts the raw materials into clinkers.

Currently, dry process kilns account for about 78% of cement production in Europe, with semi-dry and semi-wet process kilns contributing another 16%, and the remaining 6% coming from wet process kilns.

Wet process kilns in Europe are generally expected to be replaced by dry process systems upon renewal, similar to upgrades expected for semi-dry and semi-wet systems. On average, pyroprocessing systems in the EU and US have a thermal efficiency of below 35%, which is considered low.

This efficiency is even lower in developing countries. Improvements in this area are expected to arise from enhanced energy management, upgrades to existing equipment (such as replacing wet kilns and adding preheaters and precalciners), adopting new pyroprocessing technologies (like fluidised bed systems), and investing in long-term research and development to innovate new processes for cement manufacturing.

Japan is at the forefront of energy efficiency in the cement industry.

In terms of energy efficiency, Europe averages 4.1 GJ/t of cement, which does not match Japan’s more efficient 3.1 GJ/t. In comparison, the average energy consumption in the US (5.3 GJ/t) and China significantly exceeds that of Europe.

The energy balances for major pyroprocessing systems reveal where energy losses occur, presenting opportunities to enhance energy efficiency and reduce fuel-based CO2 emissions.

Particularly, the data suggests substantial efficiency gains are possible by transitioning from wet to dry cement processes. The table detailing energy use identifies specific areas and scales of potential improvements by managing energy losses through equipment or practice enhancements.

Thermal Energy Balances

Through energy audits, including kiln system performance testing and calculation of mass and heat balances, specific opportunities for improving energy efficiency and lowering CO2 emissions can be identified. A cement manufacturing energy audit should at a minimum address the energy use and recommend potential actions, such as:

- Lower kiln exit gas losses

- Install devices to provide better conductive heat transfer from the gases to the materials, e.g., kiln chains

- Operate at optimal oxygen levels (control combustion air input)

- Optimise burner flame shape and temperature

- Improve or add additional preheater capacity

- Lower moisture absorption opportunities for raw meal and fuels: avoiding the need to evaporate adsorbed water

- Lower dust in exhaust gases by minimizing gas turbulence: dust carries energy away from the kiln where it is captured in dust collectors; the dust is recycled into the raw meal and fed into the kiln where it is reheated

- Lower clinker discharge temperature, retaining more heat within the pyro processing system

- Lower clinker cooler stack temperature

- Recycle excess cooler air

- Reclaim cooler air by using it for drying raw materials and fuels or preheating fuels or air

- Lower kiln radiation losses by using the correct mix and more energy efficient refractories to control kiln temperature zones

- Lower cold air leakage

- Close unnecessary openings

- Provide more energy efficient seals

- Operate with as high a primary air temperature as possible

- Optimise kiln operations to avoid upsets.

Wet cement production involves mixing raw materials (limestone and clay or loam) with water in order to produce slurry. Further in the process, water is evaporated from the homogenized mixture and this step in the production requires significant amounts of energy.

The raw meal (dried slurry) is subjected to high temperatures in a rotary kiln, where the reaction of calcination takes place (its final products are lime and CO2). The lime is further influenced by the temperatures of 1,400 to 1,450 oC. This reaction, called sintering, results in clinker. The final stage of cement production is fine crushing of clinker and mixing the substance with mineral components, such as slag, fly ash or gypsum.

In the case of dry cement production, the raw materials are mixed without water and therefore the evaporation process can be omitted. The latter technology could reduction the energy consumption from the ‘wet’ to the ‘dry’ process by over 50%.

Existing technology in the cement industry can be upgraded in several ways. Table 26‑3 shows, based on data from US cement plants, the impact of possible upgrading measures such as from wet to dry processes and within the latter category, the impact of using preheater and precalciner technologies.

Energy use in the US

Various emerging technologies are undergoing testing and implementation, including fluidised-bed kilns. Since the mid-1990s, several large-scale fluidised-bed kiln pilots with capacities of 200 tonnes/day have shown considerable energy savings.

For example, a full-scale fluidised-bed system capable of processing 3,000 tonnes/day could match the efficiency of the most advanced US kiln equipped with a preheater and precalciner, and be 37% more efficient than the average US cement plant.

The capital costs for fluidised-bed systems are approximately 12% lower than those for a contemporary cement facility, while their operating costs are about 75% of those of a modern plant.

However, compared to older, fully capitalized kiln-based plants, fluidised bed systems are relatively costly, making them more suitable for future expansions rather than current replacements.

Another obstacle in adopting fluidised-bed technology is the hesitation to commit to large capital investments, especially since these systems have only been tested at smaller scales.

Cement plants, which have substantial industrial thermal energy needs, also present opportunities for co-generation of electricity and/or steam, especially if integrated into the original plant design.

Such integration could notably enhance the energy efficiency of certain manufacturing processes. Currently, five cement manufacturing facilities generate electricity on-site through co-generation systems.

The use of waste heat in preheater heat exchange systems generally offers more energy efficiency than generating electricity through co-generation, which has a relatively low thermal to electrical energy conversion rate (typically requiring about 10,481 Joules to produce 1 kWh).

While it’s feasible to generate steam at cement plants, these facilities usually have minimal steam requirements and are often situated in remote areas, limiting the market for any surplus steam generated.

Contribution of Technology to Economic Development

An important benefit of enhancing energy efficiency in the cement industry would be the reduction in energy costs. Broadly speaking, in the EU cement industry the energy bill represents about 40% of total production costs, while European cement production techniques are amongst the most energy efficient in the world.

Since the 1970s, in Europe the energy required for producing cement has fallen by about 30% and the scope for further improvements has became rather small. However, larger energy cost savings are still possible in other parts of the world.

In cement manufacturing, cost-effective efficiency gains in the order of 10% to 20% are already possible using commercially available technologies. The energy intensity of most industrial processes is at least 50% higher than the theoretical minimum determined by the basic laws of thermodynamics.

Energy efficiency tends to be lower in regions with low energy prices. Cross-cutting technologies for motor and steam systems would yield efficiency improvements in all industries, with typical energy savings in the range of 15% to 30%.

The payback period can be as short as two years, and in the best cases, the financial savings over the operating life of improved systems can run as high as 30% to 50%. In those processes where efficiency is close to the practical maximum, innovations in materials and processes would enable even further gains.

Climate

Cement manufacturing produces CO2 as it requires very high temperatures to burn raw materials and give the clinker its unique properties.

CO2 is generated from three independent sources:

- De-carbonation of limestone in the kiln (about 525 kg CO2 per tonne of clinker)

- Combustion of fuel in the kiln (about 335 kg CO2 per tonne of cement)

- Use of electricity (about 50 kg CO2 per tonne of cement)

There are three central measures by which the cement industry may save direct CO2 emissions in the immediate future:

- Improvement of energy efficiency (a maximum of 2% is still feasible)

- Reduction of clinker/cement ratio (introduction of useful industrial by-products)

- Increase in the use of waste as alternative fuel (national initiatives, adequate national implementation of certain directives regarding specific waste)

Based on the IEA (2008) analysis for blended cements, in total, the savings potential in this case amounts to 300 Mt CO2 to 450 Mt CO2 by 2050. The main approaches to this are to use:

- Blast-furnace slag that has been cooled with water, rather than air. About half of all blast-furnace slag is already used for cement-making where the slag is water-cooled and where transport distances and costs are acceptable. If all blast-furnace slag were used, this would yield a CO2 reduction of approximately 100 Mt CO2.

- Fly ash from coal-fired power plants. But the carbon content of fly ash can affect the concrete setting time, which determines the quality of the cement. To be used as clinker substitute, high-carbon fly ash must be upgraded. Technologies for this are just emerging. Special grinding methods are also being studied as a way to increase the reaction rate of fly ash, allowing the fly ash content of cement to increase to 70% compared with a maximum of 30% today (Justnes et al., 2005). China and India have the potential to significantly increase the use of fly ash. If the 50% of all fly ash that currently goes to landfill could be used, this would yield a CO2 reduction of approximately 75 Mt.

- Steel slag. The CemStar process, which uses a 15% charge of air-cooled steel slag pebbles in the rotary kiln feedstock mix, has been developed and successfully applied in the United States, resulting in a CO2 reduction of approximately 0.47 t/t steel slag added (Yates et al., 2004). In China, there are about 30 steel slag cement plants with a combined annual output of 4.8 Mt. Steel slag quality varies and it is difficult to process, which limits its use. If the total worldwide BOF and EAF steel slag resource of 100 Mt to 200 Mt per year was used this way, the CO2 reduction potential would be 50 Mt to 100 Mt per year. Further analysis is needed to validate the viability of this option. Other materials that could be used to a greater extent as clinker substitutes include volcanic ash, ground limestone and broken glass. Such approaches could alleviate clinker substitute availability problems, and possibly pave the way to a 50% reduction of energy use and CO2 emissions. In the long term, new cement types may be developed that do not use limestone as a primary resource. These new types are called synthetic pozzolans. The technological feasibility, economics and energy effects of such alternative cements remain speculative.

- Blended cements offer a major opportunity for energy conservation and emission reductions, but their use would in many cases require revisions to construction standards, codes and practices. In total, the savings potential for blended cements amounts to 300 Mt CO2 to 450 Mt CO2 by 2050. Learning rate for CCS cement kilns under a current cost of 200 USD/ tCO2, is around 5%, while the cost target to reach commercialization in USD is 75.

CO2 Emission Reduction Potentials Based on Best Available Technology

For calculation of these GHG emission reductions, it is recommended to apply the approved methodologies for consolidated methodology for increasing the blend in cement production, methodology for greenhouse gas reductions through waste heat recovery and utilization for power generation at cement plans, switching fossil fuels, energy efficiency and fuel switching measures for industrial facilities.

Emissions reduction through partial substitution of fossil fuels with alternative fuels or less carbon intensive fuels in cement manufacture project (large scale activities) which has been developed under the Clean Development Mechanism of the UNFCCC Kyoto Protocol (CDM).

This methodology helps to determine a baseline for GHG emissions in the absence of the project (i.e. business-as-usual circumstances), how emission reductions below this baseline can be calculated, and how these reductions can be monitored.

Financial Requirements and Costs

Substantial growth in cement demand is anticipated in developing regions such as parts of the Asia/Pacific, Eastern Europe, Africa/Middle-East, and Latin America, driven by a strong construction sector outlook.

Countries like Vietnam, Thailand, Ukraine, Turkey, and Indonesia are predicted to see notable increases in cement demand in percentage terms.

In contrast, growth will be more modest in developed areas like the USA, Japan, and Western Europe, where maintenance and repair activities will largely fuel cement demand. However, a resurgence in construction spending in Germany and Japan is expected to support growth in these developed markets after a period of decline.

The cement industry has invested heavily in innovative production techniques. Significant resources have been allocated to developing emerging technologies that are less controversial and non-polluting, although many of these are still under development, technically complex, and not yet economically viable for many developing countries.

In the short term, it is expected that the cement industry will continue to rely primarily on pyroprocessing and grinding mills. The most common method of cement production involves kilns, which, while standardized in the developed world, may pose financial challenges in developing regions.

Despite higher energy costs, tube mills are preferred in some settings due to their lower operational and maintenance costs, although investment costs can vary significantly due to site-specific factors. Decisions on mill type may also be influenced by non-cost factors such as the moisture content of raw materials, with vertical roller mills being ideal for wetter materials.

In 1999, ten leading cement companies, which account for about one-third of global cement production, initiated the Cement Sustainability Initiative (CSI) under the World Business Council for Sustainable Development (WBCSD).

The CSI aims to reduce the industry’s ecological footprint, enhance its social contributions, and increase stakeholder engagement, showcasing the industry’s commitment to sustainability.