Industrial insulation materials are broadly categorized into three types: mineral fiber, cellular plastic, and plant/animal-derived products.

Mineral fiber insulation includes materials such as:

- Rock wool

- Slag wool

- Glass wool

These materials are melted at high temperatures and spun into fibers, then bound together to form rigid sheets or batts. Mineral fiber is notable for its potential for reuse and recycling at the end of its lifecycle, provided it is removed under the right conditions.

Cellular plastic products, derived from petroleum, encompass materials like:

- Rigid polyurethane

- Phenolic

- Expanded polystyrene

- Extruded polystyrene

These are available in forms such as loose fill, rigid sheets, and foam.

Historically, their production involved ozone-depleting HCFCs, though modern processes use environmentally neutral hydrocarbons instead. It’s crucial to verify that cellular plastic insulation products are produced without ozone-depleting substances.

While recyclable, cellular plastic is challenging to process and is often incinerated for energy recovery at the end of its life.

Plant and animal-derived insulation options include materials like cellulose fiber, sheep wool, cotton, and flax. These products are characterized by low embodied energy and are made from renewable resources.

They are available as fibers, batts, or compressed boards and undergo chemical treatments to enhance properties such as fire resistance and pest resistance. However, these treatments complicate their disposal, making them less suitable for energy recovery through incineration at their end of life.

Building envelope thermal insulation is a proven technology that contribute to energy-efficient buildings. Two new trends have recently been observed in the development of thermal insulation – the development of phase change materials (PCMs) and innovative use of raw natural elements as thermal insulation.

Phase change materials (PCMs) work based on the latent heat storage principle. “When temperature rises, the temperature of a latent heat store does not increase but the medium changes from one physical state to another, and by this means it stores energy.

Therefore the take up of energy cannot be detected by touch. The temperature only rises detectably after a complete change of phase has taken place. When a change takes place, the latent heat involved is equal to the heat of melting or crystallisation of the storage medium.

The advantage of PCMs is that large amounts of heat or cold can be stored within small temperature ranges.”

Because phase changes between solid and liquid, PCMs (such as paraffin) have to be encapsulated prior to use. Paraffin-based PCMs have melting points ranging from 24 to 26°C and are mostly used to prevent heat gain in hot weather conditions.

Encapsulated paraffin PCMs are mixed with mortars applied on building envelopes. Used in combination with night cooling strategies, PCMs can be effective in preventing heat gain through the building envelope.

At present, PCMs are at the research and development, and test bedding stage. PCMs are promising technologies because they are lightweight, easy to apply and blend in well with conventional construction methods.

The second development trend of thermal insulation is the innovative use of raw natural materials as thermal insulation. An example is the use of untreated straw bales as insulation.

In order to overcome a firehazard issue, straw bales are sandwiched between fire-resistant cladding materials, such as metal-based cladding, or glass panels to create aesthetic effects by making straw bales visible. Another natural element used as thermal insulation is air, which has a thermal conductivity of about 0.025W/mK.

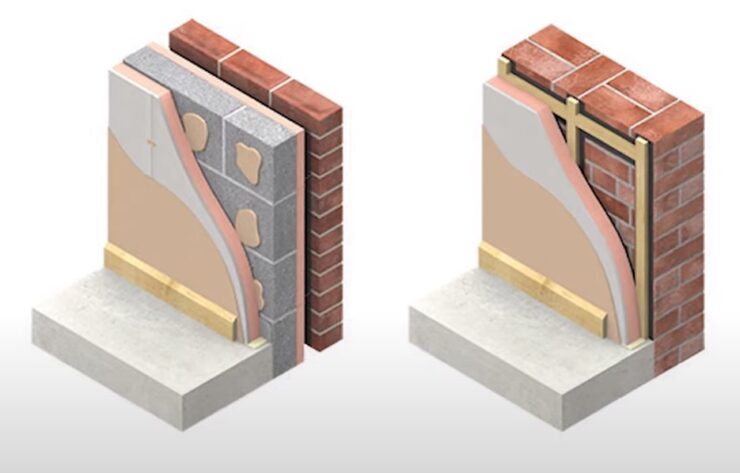

Its application is often found in the provision of an air gap in cavity wall construction to enhance thermal insulation performance. Use of air gaps is not sufficient for buildings in temperate regions, but could be sufficient for buildings in mild climate conditions.

Air Gap Used in Conjunction with Insulated Timber-Brick Wall

In developed and industrialized nations, building codes mandate minimum insulation levels for building envelopes, facilitating the adoption of thermal insulation technologies. In many developing countries, particularly the least developed ones and those with remote rural areas, such regulations are often absent.

Thus, implementing thermal insulation on a large scale in these regions requires the establishment of supportive policies, including both incentives and mandatory measures.

Furthermore, the production of cellular plastic insulation has historically involved ozone-depleting substances like HCFCs. Although manufacturers have now shifted to using more environmentally benign hydrocarbons, it remains crucial to verify that cellular plastic insulation products are free from ozone-depleting agents.

Effective local regulations prohibiting products made using harmful processes are essential.

The successful application of building envelope thermal insulation hinges on meticulous design, skilled workmanship, and the correct selection, handling, and installation of products. Capacity-building initiatives, such as workshops for design professionals and construction workers, are vital to ensure these practices are followed.

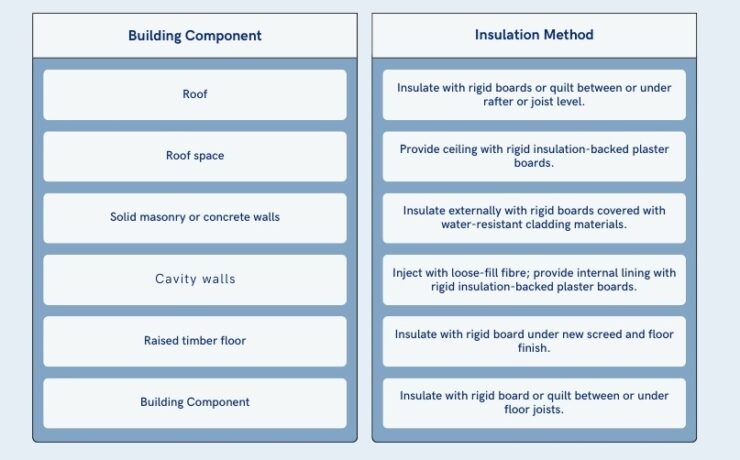

Building envelope thermal insulation is integral to the construction details of floors, walls, and roofs/ceilings, both in new constructions and in retrofitting existing buildings. Retrofitting, unlike new construction, requires careful identification of suitable locations for incorporating thermal insulation to ensure effectiveness.

The key locations are:

For both new builds and renovations of existing structures, it’s crucial to ensure that thermal insulation products are installed under optimal conditions to maintain their effectiveness throughout their lifespan.

Mineral fiber insulation is available in batts, rolls, and loose fill, suitable for both off-site and on-site applications. However, its open structure makes it permeable to air and vapor, potentially diminishing its insulating ability.

To combat this, it’s essential to use foil backing and meticulous installation techniques to shield the insulation from vapor and water exposure, which could stem from condensation between the external wall and the insulation layer, or from water leaks within the wall.

Cellular plastic insulation is known for its durability and resistance to decay and pests. Available as rigid sheets or sprayable foam, this material adheres to the building envelope when sprayed, expanding to fill gaps post-installation, even around electrical and plumbing installations.

Insulation derived from plant or animal materials is more prone to pest infestation. Although these products are typically treated with chemicals during manufacturing, these treatments can diminish if the insulation becomes damp or is exposed to high humidity.

It’s advisable to install these materials in dry conditions and ensure protective measures like adequate backing are in place.

Proper installation and detailing to eliminate air leaks are essential for all types of thermal insulation. Special care is needed when fitting insulation around electrical fixtures and within wall frames to ensure a tight seal.

For buildings in extreme climates, conducting thorough building envelope commissioning is recommended to ensure the insulation performs optimally, particularly in large-scale constructions. This involves meticulous planning and execution to maximize energy efficiency and durability.

Status of the Technology and its Future Market Potential

Building envelope thermal insulation products have been widely used in temperate regions. In many developed and industrialised countries, thermal insulation is a regulatory requirement for energy efficiency and occupant health purposes, which provide a fairly constant market for the thermal insulation manufacturers.

The market for building fabric thermal insulation products is not as large in hot and humid tropical regions, where natural ventilation, not air-tightness, is a more appropriate strategy for thermal comfort. In this context the use of thermal insulation is not extensive, and the use of an air gap in the cavity wall for the west facing façade to prevent heat gain from hot afternoon sun is found to be sufficient.

Roof insulation, however, is applicable in all climate regions, including the hot tropical bell. In the Caribbean, for example, roof insulation has generally been accepted as a “proven energy conservation solution” with mineral (glass) fibre generally the lead product.

Contribute to Socio-Economic Development

The primary contribution of building envelope thermal insulation is to provide thermal comfort to its occupants. This supports healthy living environments and better productivity at workplaces.

Thermal insulation reduces unwanted heat loss or heat gain through a building envelope. This, in turn, reduces energy demand for cooling and heating of buildings, and thus is a mitigation measure to reduce GHG emissions.

Large-scale implementation of thermal insulation has also been proven to be an economic stimulus. In the European region alone, there were nearly 12,000 companies, with a total of 400,000 employees, operating in the value stream derived from cellular plastic products.

There are ample business and job creation opportunities for developing countries, if successful North-South and South-South transfer programmes for building envelope thermal insulation are in place.

Financial Requirements and Costs

The financial considerations for implementing thermal insulation in building envelopes include both the initial costs of products and their installation.

The cost of thermal insulation materials and their installation is typically calculated based on the area covered and the material’s thermal conductivity. Installation costs tend to be lower for loose fill insulation products due to their ease of installation.

However, some insulation materials, such as loose fill, may lack sufficient protection against moisture and pests, which can affect their long-term durability and effectiveness. Maintenance costs for most thermal insulation products are generally low, and products like cellular plastic require little to no maintenance.

On the other hand, materials such as mineral fiber or those derived from plants or animals might need replacement if they fail to perform optimally due to moisture absorption or pest damage.

In buildings that are naturally ventilated and located in mild climates, focusing insulation efforts on the roof and west-facing walls can be particularly effective in minimizing heat gain and can offer a better return on investment compared to insulating the entire building envelope.

Alternative insulation materials like straw bales and the use of air gaps in cavity walls usually involve minimal costs beyond the increased wall thickness, though their long-term performance can be variable. In developed and industrialized countries, mineral fiber products are competitively priced against other insulation types like cellular plastic.

In contrast, in developing countries and rural settings, insulation derived from plant or animal sources tends to be more cost-effective due to the greater availability and accessibility of these materials. Cellular plastic products are noted for their rigidity, stability, and long-term performance, making them a low-maintenance option.