A solar dryer is a pretty simple idea when you break it down. Here are the basic things it does:

Turning sunlight into heat – Anything black inside helps change the light to warmth better.

Trapping the warmth – Using something clear like plastic or glass lets the light in. But once it turns to heat, it keeps that heat from escaping back outside where it’s cooler. This helps it work even on cloudy or windy days too.

Moving the heat to the food – Both natural dryers and ones with fans use the heated air to carry the warmth over to what you’re drying.

There are a few different kinds of solar dryers. Mainly they fall into three groups:

- Natural ones rely on the air getting warmer and rising on its own to circulate the heat.

- Forced ones with a little fan pushing the air around to dry food faster.

- Tunnel dryers that work sort of like a long tube to move air through.

The Tunnel Dryer

The tunnel dryer has a pretty straightforward design. Here are the main parts:

It’s shaped kind of like half a circle made from a plastic-covered frame. This plastic sheet is special so it doesn’t get ruined by sunlight.

Unlike other dryers, a tunnel dryer is big enough for a person to walk right inside. The curved plastic roof and walls work together to capture and circulate the warm air.

Some key advantages of the tunnel design include:

- Lots of space inside to spread out racks of food for drying

- A person can easily turn or rotate items as they dry

- Airflow all around helps speed up the process

- The sheltered area protects from rain or animals

- Tall walls and arched tops create a strong natural convection current

Natural Convection Dryer

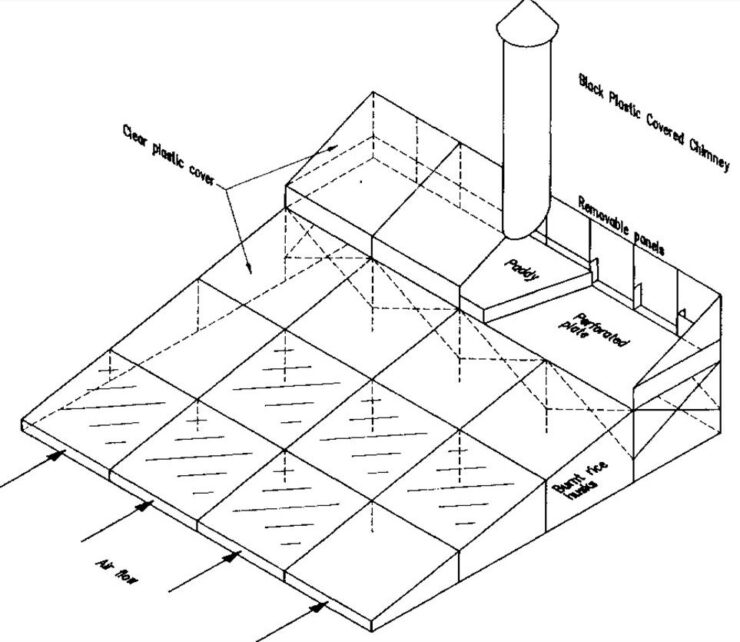

Natural convection dryers are usually a good size for drying crops right on the farm. One design that researchers tested a lot is shown in Figure 3. This dryer is big: the collector where sunlight heats the air is over 14 feet long and 23 feet wide. The area to spread out the food is almost 4 feet long and 23 feet wide.

It has three main sections. First, the collector warms the air. Then the drying bin, which is made from bamboo mats in this one. Finally, a chimney to help the hot air rise and circulate through. The chimney is covered in black plastic to absorb even more heat from the sun.

One downside is how tall it is. High winds could blow it over easier. The plastic also needs replacing every 1-2 years as it breaks down in the sunlight.

Natural Convection dryer small-scale design

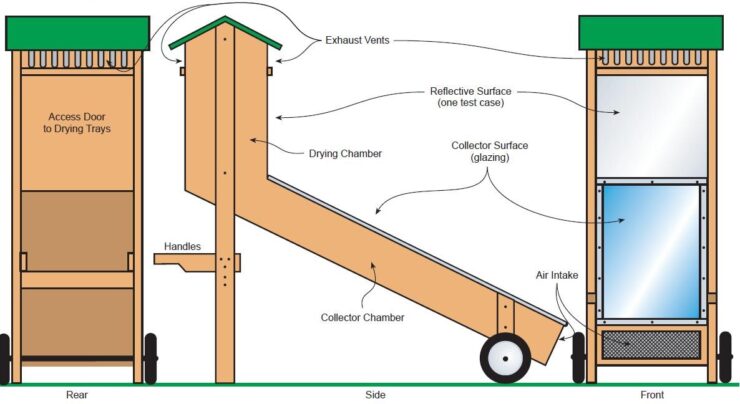

These solar dryers are pretty basic wooden boxes with vents on the top and bottom. Metal racks that hold the food slide right into the boxes. Attached to the bottom is a solar air heater facing south. It’s got a clear plastic cover and a black metal strip inside that heats up from the sun.

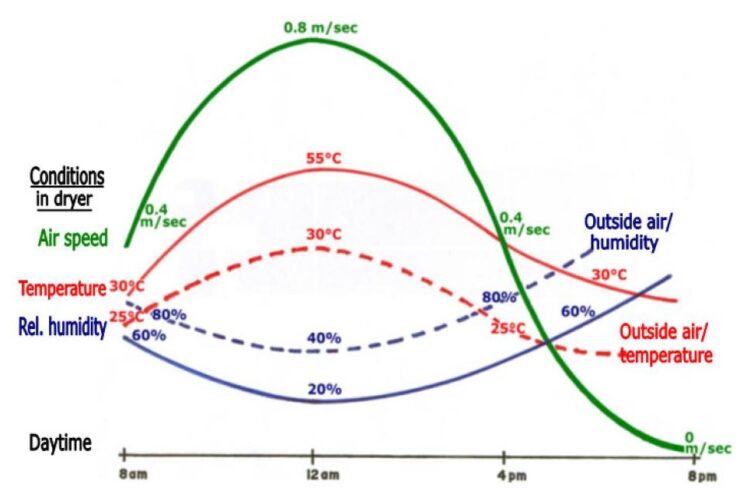

Air comes in the bottom of the heater and warms up off the black strip. Then the hot air rises past the racks of food on its way out the top vents. While working, these dryers get the air warm – between 130 to 180 degrees Fahrenheit. That’s just right for drying most foods well and killing any germs too.

You can fit a lot inside – the racks hold 35 to 40 apples or peaches each cut into thin slices. Best of all, with one of these dryers you can dry the food in just one day, even if it’s kinda cloudy or humid out.

Forced convection dryers are built pretty similarly, but they need power for the fans that move the air. This type doesn’t require the collector to be on an angle like natural ones. It can be laid out flat, with the fan at one end blowing into the drying area on the other side.

Another good thing is they don’t rely on the sun’s heat as much. The fans circulate the air no matter what the weather is like. This lets them work even when a natural dryer wouldn’t due to clouds, wind or rain.

Proper airflow is really important so the food dries safely. Not enough moving air can spoil what you’re drying. A forced dryer’s fans ensure circulation stays strong, even when it’s not that warm and sunny outside.

Adding a small solar panel to run the fan power makes a lot of sense. Then it’s renewable energy preserving your harvest without wasting electricity.

Feasibility of technology and operational necessities

The main reason to dry is to preserve what you’ve grown or made. But it’s not just about getting the moisture out. How you dry affects other things too.

- Moisture level – Drying needs to get food to the right amount of moisture for however long you plan to store it and where. Some foods need more drying than others. Partially dried food can spoil the whole batch.

- Nutrition – High temperatures are no good and can hurt what’s healthy in the food.

- Mold – How fast mold grows depends on moisture, heat, and any damage to the food.

- Looks and smell – Like how drying rice the wrong way can change its color. Burners need caring for.

How the technology contribute to socio-economic development and environmental protection?

A solar food dryer can save on fuel and electricity costs compared to dryers needing outside power. It replaces what you’d spend on fuel or grid power.

Solar dryers also speed things up versus sun drying alone. While dryers with fans or burners might give steadier airflow and more heat, they could cost too much for farmers on a tight budget. Electricity may not be available or too pricey, and fuel-powered dryers come with big startup and running costs.

Food dried in a solar dryer is healthier and cleaner than sun drying. The closed system keeps it safer from dirt and bugs. It also protects from rain and dust like sun drying’s open setup can’t.

In areas where farmers grow crops without good drying options, they have to sell right after harvest. When there’s a big harvest, they may have to lower prices fast to keep food from spoiling. A solar dryer could help prevent money losses during those times. Dried food stores longer while keeping quality. Dried goods may sell for more as special products, like dried meat used in different treats.

Drying reduces volume too. So along with longer shelf life, dried food also ships more easily to more markets for farmers to make a profit.

Financial requirements

Natural convection dryers are pretty cheap to build. They mostly use stuff that’s easy to find, like wood, bamboo, or other strong materials. The biggest costs may be plastic or glass sheets to trap heat inside. But the natural kind doesn’t cost much to run after that, just labor.

Forced dryers have higher upfront and running costs. Buying the fan and powering it costs more money over time compared to natural dryers without fans.

Dried foods might bring in more cash at the market too. When it’s not that food’s regular season, the dried version could cost more since it’s not as easy to find.