Fog harvesting technology typically employs a single or double-layer mesh net, which is held upright by two posts. The size of these mesh panels can vary.

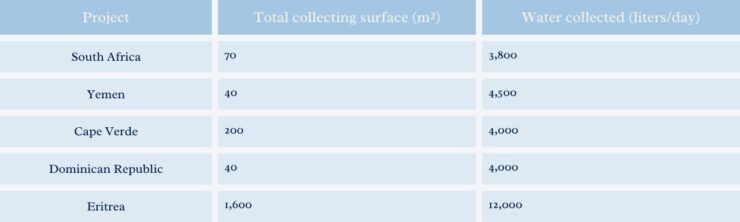

for example, the University of South Africa used a large 70 m² mesh in their research, while in Yemen, multiple small Standard Fog Collectors (SFC) of 1 m² each were utilized.

The mesh is generally made from materials like nylon, polyethylene, or polypropylene netting, often referred to as ‘shade cloth’. These materials can be produced in different densities to capture varying amounts of water from the passing fog.

These collectors are ideally placed on ridgelines, aligned perpendicular to the prevailing winds to maximize water capture. The number and size of the meshes installed depend on the local topography, the community’s water needs, and the availability of financial and material resources.

FogQuest suggests an optimal setup of single mesh units spaced at least 5 meters apart, with additional collectors positioned upstream at distances ten times greater than the adjacent ones.

In a project by the University of South Africa, multiple mesh panels were clustered to increase the catchment area and enhance structural stability in windy conditions.

The system operates by gravity, with water droplets collected on the mesh running downward into a gutter. From there, the water is channeled through pipes into a storage tank or cistern.

Water production from a fog collector can range between 200 to 1,000 liters per day, varying daily and seasonally. Collection efficiency is enhanced by larger fog droplets, higher wind speeds, and narrower mesh fibers.

The dimensions of the conveyance system and storage device will depend on the scale of the scheme. Storage facilities should be provided for at least 50 per cent of the expected maximum daily volume of water consumed.

For agricultural purposes, water is collected in a regulating tank, transferred to a reservoir and then finally into an irrigation system that farmers can use to water their crops.

Operation and maintenance are relatively simple processes once the system has been properly installed. Nevertheless, an important factor in the sustainability of this technology is the establishment of a routine quality control programme which should include the following tasks:

- Inspection of mesh nets and cable tensions to prevent loss in water harvesting efficiency and avoid structural damage

- Maintenance of nets, drains and pipelines to include removal of dust, debris and algae

- Maintenance of the storage tank or cistern to prevent accumulation of fungi and bacteria

- Where spare parts are not available locally, it is recommended that a stock of mesh and other components be kept in reserve as local supply might be restricted, especially in remote mountainous regions.

Drought caused by climate change is leading to reductions in the availability of fresh water supplies in some regions. This is having an impact on agricultural production by limiting opportunities for planting and irrigation.

Fog harvesting provides a way of capturing vital water supplies to support farming in these areas. Furthermore, when used for irrigation to increase forested areas or vegetation coverage, water supplies from fog harvesting can help to counteract the desertification process.

If the higher hills in the area are planted with trees, they too will collect fog water and contribute to the aquifers. The forests can then sustain themselves and contribute water to the ecosystem helping to build resilience against drier conditions.

How Much Does it Cost?

The costs of fog harvesting systems vary based on factors such as the size of the fog catchers, the quality and accessibility of materials, labor, and the location of the installation. Small fog collectors typically cost between $75 and $200 each to construct.

Larger fog collectors, which cover an area of 40 square meters, range from $1,000 to $1,500 each and can have a lifespan of up to ten years.

For a village project capable of producing about 2,000 liters of water daily, the initial cost is approximately $15,000. Systems with multiple units are more cost-effective per unit of water produced. They also offer flexibility as the number of panels can be adjusted based on changing climatic conditions and water demand.

Involving the community in the construction of fog harvesting systems can significantly reduce labor costs.

Institutional Requirements

It is generally recommended that the local population is involved in the construction of the project. Community participation helps to remove labour costs and also helps to ensure a sense of ownership by the community and a commitment to maintenance.

A community management committee could be set up and consist of trained individuals responsible for repair and maintenance tasks, helping to ensure the long-term sustainability of the technology. In the initial stages, government subsidies may be required to buy raw materials and fund technical expertise.

A range of meteorological and geographic information is required for choosing a site to implement fog harvesting technology, including predominant wind direction and the potential for extracting water from fogs (such as frequency of fog occurrence and fog water content).

A feasibility study and pilot-scale assessment should also be carried out to assess the magnitude and reliability of the fog water source.

Potential Challenges in Implementation

Several challenges and issues have emerged from fog harvesting projects implemented to date:

- Where fog is a seasonal source, water has to be stored in large quantities for dry season use

- If not properly maintained, water quality becomes an issue during low-flow periods

- Fog water collection requires specific environmental and topographical conditions, limiting its application to specific regions

- Procurement and transportation of materials is hindered by remote locations and steep terrain

- Strong winds and snow fall can result in structural failure during the winter season

- Water yield is difficult to predict, requiring feasibility studies prior to large scale implementation

- For harvesting to be effective, frequent fogs are needed and sufficient water collected for the investment to be cost-effective. This limits the technologies to areas with specific conditions

- There are few commercial producers of mesh currently in operation, with main suppliers located in the Chile